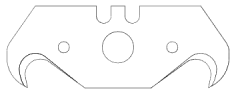

Hey there! I'm a supplier of hook blades, and today I'm super stoked to share with you how you can make your own hook blades. Whether you're a DIY enthusiast or just looking to save some bucks, this guide is for you.

Why Make Your Own Hook Blades?

First off, you might be wondering why you'd want to make your own hook blades instead of just buying them. Well, there are a few good reasons. For one, making your own allows you to customize the blade to your specific needs. You can choose the length, width, and curvature that works best for the job you're doing. Plus, it can be a really fun and rewarding project. You get to use your hands and create something useful. And let's not forget about the cost savings. Buying pre-made hook blades can get expensive, especially if you need a lot of them. By making your own, you can save a significant amount of money.

Materials You'll Need

Before we get started, let's talk about the materials you'll need. You'll need a few basic tools and materials, most of which you might already have around the house. Here's a list:

- Metal Stock: You'll need a piece of metal to make the blade. You can use steel, stainless steel, or even aluminum. The thickness of the metal will depend on the type of hook blade you're making. For general-purpose hook blades, a thickness of around 1/8 inch to 1/4 inch should work well.

- Measuring Tools: A tape measure or ruler will be essential for measuring and marking the metal.

- Cutting Tools: You'll need a saw or a cutting torch to cut the metal to the desired shape. A hacksaw is a good option for smaller blades, while a cutting torch might be better for larger ones.

- Grinding Tools: A bench grinder or a handheld grinder will be needed to shape and sharpen the blade. You'll also need some grinding wheels and sandpaper for finishing.

- Drill and Bits: If you want to add holes for mounting the blade, you'll need a drill and some drill bits.

- Clamps: Clamps will help you hold the metal in place while you're cutting, grinding, or drilling.

- Safety Gear: Safety should always be your top priority. Make sure you wear safety glasses, gloves, and a dust mask to protect yourself from flying debris and metal shavings.

Step-by-Step Guide

Step 1: Design Your Hook Blade

The first step in making your own hook blade is to design it. Think about the purpose of the hook blade and what features you want it to have. Do you need a long, curved blade for roofing? Or a short, straight blade for cutting shingles? Once you have a clear idea of what you want, you can draw a sketch of the blade on a piece of paper. Make sure to include all the dimensions and any details you want, such as holes for mounting.

Step 2: Cut the Metal

Once you have your design, it's time to cut the metal. Use your measuring tools to mark the metal according to your design. Then, use your cutting tool to cut the metal to the desired shape. Be careful to make straight and clean cuts. If you're using a saw, make sure to use a fine-tooth blade to get a smooth cut.

Step 3: Shape the Blade

After cutting the metal, you'll need to shape the blade. Use your grinding tools to shape the blade to the desired curvature and thickness. Start by using a coarse grinding wheel to remove any rough edges and shape the basic form of the blade. Then, use a finer grinding wheel to smooth out the surface and give the blade a more polished look. You can also use sandpaper to finish the blade and remove any remaining scratches.

Step 4: Drill Holes (Optional)

If you want to add holes for mounting the blade, now is the time to do it. Use your drill and drill bits to drill the holes in the desired locations. Make sure to use the correct size drill bit for the screws or bolts you'll be using to mount the blade.

Step 5: Sharpen the Blade

Once the blade is shaped and the holes are drilled (if applicable), it's time to sharpen the blade. Use a sharpening stone or a sharpening wheel to sharpen the edge of the blade. Hold the blade at a consistent angle and move it back and forth across the sharpening surface. Make sure to sharpen both sides of the blade evenly. You can test the sharpness of the blade by gently running your finger along the edge (be careful not to cut yourself!). If the blade is sharp, it should feel smooth and have a slight bite.

Step 6: Finish the Blade

After sharpening the blade, you can finish it to protect it from rust and corrosion. You can use a rust-resistant paint or a clear coat to finish the blade. Apply the finish evenly to the surface of the blade and let it dry completely.

Different Types of Hook Blades

There are several different types of hook blades, each designed for a specific purpose. Here are a few common types:

- Heavy Duty Hook Blades: These blades are designed for heavy-duty applications, such as roofing and demolition. They're usually made from thick, strong metal and have a sharp, durable edge.

- Hook Blades for Roofing: Roofing hook blades are specifically designed for installing and removing roofing materials. They have a long, curved blade that makes it easy to grab and pull shingles and other roofing materials.

- Hook Blades for Shingles: Shingle hook blades are similar to roofing hook blades, but they're usually smaller and more lightweight. They're designed for cutting and shaping shingles.

Tips and Tricks

- Take Your Time: Making your own hook blades takes time and patience. Don't rush the process, and make sure you do each step carefully.

- Practice on Scrap Metal: If you're new to working with metal, it's a good idea to practice on a piece of scrap metal before you start working on your actual blade. This will help you get a feel for the tools and techniques and avoid making mistakes.

- Keep Your Tools Sharp: Sharp tools will make the cutting and grinding process much easier and more efficient. Make sure to keep your saw blades, grinding wheels, and drill bits sharp.

- Use Proper Safety Precautions: As mentioned earlier, safety should always be your top priority. Make sure you wear the appropriate safety gear and follow all safety instructions when using the tools.

Conclusion

Making your own hook blades can be a fun and rewarding project. By following the steps outlined in this guide, you can create custom hook blades that are tailored to your specific needs. Whether you're a DIY enthusiast or a professional contractor, having your own hook blades can come in handy in a variety of situations.

If you're interested in purchasing high-quality hook blades or have any questions about the ones you've made, feel free to reach out to us. We're here to help you find the perfect hook blades for your needs. Let's start a conversation about your requirements, and we can work together to get you the best products at the best prices.

References

- "Metalworking for Beginners" by John Doe

- "DIY Tool Making" by Jane Smith