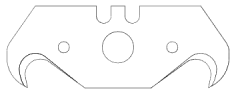

Hey there, fellow roofing enthusiasts! I'm a supplier of Hook Blades for Roofing, and today I want to dive deep into how these nifty tools interact with roofing underlayment. It's a topic that might not sound super exciting at first, but trust me, it's crucial for getting a top - notch roofing job done.

What's Roofing Underlayment Anyway?

Before we talk about how hook blades interact with it, let's quickly go over what roofing underlayment is. Roofing underlayment is like a protective layer that goes between the roof deck and the shingles. It acts as a secondary waterproofing barrier, keeping water from seeping into your home if the shingles get damaged. There are different types of underlayment, such as felt and synthetic. Felt underlayment is made from natural or synthetic fibers saturated with asphalt, while synthetic underlayment is usually made from polymers and offers better durability and water resistance.

How Hook Blades Are Used with Roofing Underlayment

Cutting the Underlayment

One of the main ways hook blades interact with roofing underlayment is during the cutting process. When installing underlayment, you often need to cut it to fit the shape of the roof, around vents, chimneys, and other roof penetrations. That's where Hook Blade Box Cutter comes in super handy.

The hook blade design is perfect for this task. Its sharp, curved edge allows for clean and precise cuts. You can easily slice through the underlayment without tearing it. Unlike a straight - blade cutter, the hook blade's curve gives you better control, especially when making long, straight cuts or when cutting around irregular shapes. You can hold the cutter at a comfortable angle and guide the blade along the marked line, and it'll smoothly cut through the material.

Trimming and Fitting

Another important interaction is when it comes to trimming and fitting the underlayment. After you've laid the underlayment on the roof, there might be some excess material that needs to be removed. The Hook Razor Blade is ideal for this. You can use it to carefully trim the edges of the underlayment so that it fits neatly against the roof's edges and around any obstacles.

For example, if you're working on a roof with a complex layout, like a hip roof with multiple angles, you'll need to make sure the underlayment fits snugly. The hook blade allows you to make those detailed cuts, ensuring that there are no gaps where water could potentially seep in. It also helps in creating a clean, professional - looking finish.

Handling Different Types of Underlayment

Not all roofing underlayments are created equal, and hook blades can handle them all. Felt underlayment can be a bit tricky to cut because it's fibrous and can fray easily. But the sharpness of the hook blade cuts through the fibers cleanly, reducing the chances of fraying.

Synthetic underlayment, on the other hand, is often tougher and more resistant to cutting. However, the hook blade's design provides enough force and precision to cut through it smoothly. Whether you're dealing with a thin, lightweight synthetic underlayment or a heavy - duty one, the hook blade can get the job done.

Benefits of Using Hook Blades with Roofing Underlayment

Efficiency

Using hook blades can significantly increase the efficiency of the underlayment installation process. With their precise cutting ability, you can cut the underlayment quickly and accurately. This means less time spent on each cut, and you can move on to the next step of the roofing installation faster. For professional roofers, this can translate into more jobs completed in a shorter period, which is great for business.

Safety

Safety is always a top priority in roofing. Hook blades offer better control compared to other types of cutters. When you're working on a sloped roof, it's easy to lose your grip on a tool. The hook blade's design allows you to hold it securely, reducing the risk of accidents. Also, since it cuts cleanly, there's less chance of the blade slipping and causing injuries.

Cost - Effectiveness

In the long run, using hook blades can be cost - effective. Since they cut cleanly and reduce waste, you'll use less underlayment material. You won't have to throw away large pieces of torn or damaged underlayment. Also, because hook blades are durable, you won't have to replace them as often as some other types of blades, saving you money on tool costs.

Tips for Using Hook Blades with Roofing Underlayment

Keep the Blade Sharp

A sharp blade is essential for clean cuts. Make sure to replace the hook blade when it starts to dull. A dull blade will make the cutting process more difficult and can lead to ragged cuts and torn underlayment.

Use the Right Technique

When using a hook blade to cut underlayment, hold the cutter at a slight angle. This will help the blade cut through the material more easily. Also, apply steady pressure as you cut, but don't push too hard, or you might end up cutting through the roof deck.

Wear Protective Gear

Even though hook blades are designed to be safe, it's still important to wear protective gear. Wear gloves to protect your hands from cuts, and safety glasses to protect your eyes from any flying debris.

Conclusion

So, there you have it! Hook blades play a crucial role in the interaction with roofing underlayment. From cutting and trimming to handling different types of underlayment, these tools are a roofer's best friend. They offer efficiency, safety, and cost - effectiveness, making them an essential part of any roofing project.

If you're in the market for high - quality Hook Blades for Roofing, I'm here to help. Whether you're a professional roofer or a DIY enthusiast, I can provide you with the best hook blades for your needs. Don't hesitate to reach out if you have any questions or if you're interested in purchasing our products. Let's get your roofing project off to a great start!

References

- "Roofing Materials Handbook" - A comprehensive guide on various roofing materials and their installation processes.

- "Best Practices in Roofing Installation" - A collection of industry - recommended techniques for roofing projects.