Hey there! I'm a supplier of Hook Blades for Roofing, and today I wanna chat about a super important topic: What is the maximum load that hook blades for roofing can bear?

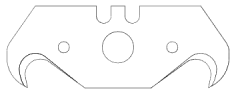

First off, let's understand what hook blades for roofing are. These are specialized tools used in the roofing industry. They're designed to cut through various roofing materials like shingles, felt, and membranes. They come in different shapes and sizes, each tailored to specific roofing tasks. For instance, Hook Razor Blade is known for its sharpness and precision, while Heavy Duty Hook Blades are built to handle tougher jobs.

Now, when we talk about the maximum load these hook blades can bear, it's not just about physical weight. It encompasses a few different factors.

Material Strength

The material the hook blade is made of plays a huge role. Most high - quality hook blades for roofing are made from hardened steel. Steel has excellent strength and durability, which allows it to withstand a fair amount of stress. For example, if you're using a hook blade to cut through thick asphalt shingles, the blade needs to be strong enough not to bend or break under the pressure.

The manufacturing process also affects its strength. Blades that are heat - treated properly have a higher resistance to wear and tear. A well - heat - treated blade can handle more force without deforming. This means it can bear a greater load when used to cut through tough roofing materials.

Blade Design

The design of the hook blade is another crucial factor. The shape of the hook can influence how the load is distributed. A well - designed hook blade will distribute the cutting force evenly across the blade. This reduces the risk of overloading a specific part of the blade, which could lead to premature failure.

Some hook blades have a wider hook area, which can spread the load over a larger surface. This is beneficial when cutting through softer materials, as it reduces the pressure per unit area. On the other hand, blades with a narrower hook are more suitable for precise cuts but may not be able to handle as much lateral force.

Cutting Conditions

The conditions under which the hook blade is used also impact its maximum load - bearing capacity. If the roofing material is wet, it can be more difficult to cut through, increasing the load on the blade. Similarly, if the material has a lot of debris or is of inconsistent thickness, the blade may experience uneven forces.

The cutting speed can also matter. Cutting too quickly can put excessive stress on the blade, especially if the material is tough. It's important to find the right balance between speed and force to ensure the blade doesn't break or wear out too fast.

Testing and Standards

Manufacturers usually conduct various tests to determine the maximum load a hook blade can bear. These tests can include applying a controlled force to the blade while it's cutting through different materials. By measuring the point at which the blade starts to deform or break, they can establish its load - bearing capacity.

There are also industry standards that govern the quality and performance of hook blades for roofing. These standards ensure that the blades meet a certain level of safety and durability. When you're looking for hook blades, it's a good idea to choose ones that comply with these standards.

Real - World Applications

In real - world roofing projects, understanding the maximum load of hook blades is essential. Roofers need to know which blade to use for different tasks. For example, when working on a large commercial roofing project with thick membranes, they'll need Heavy Duty Hook Blades that can handle the high load.

On the other hand, for a residential roofing job with standard asphalt shingles, a regular Hook Razor Blade might be sufficient. Using the wrong blade can not only lead to inefficiency but also pose a safety risk.

How to Maximize the Load - Bearing Capacity

To get the most out of your hook blades, there are a few things you can do. First, make sure you're using the right blade for the job. As I mentioned earlier, match the blade to the roofing material and the type of cut you need to make.

Keep the blades clean and sharp. A dull blade will require more force to cut through materials, increasing the load on the blade. You can use a sharpening tool to maintain the blade's edge.

Store the blades properly. Avoid exposing them to moisture or extreme temperatures, as these can weaken the blade over time.

Conclusion

So, to sum it up, the maximum load that hook blades for roofing can bear depends on factors like material strength, blade design, cutting conditions, and manufacturing quality. By understanding these factors, roofers can choose the right hook blades for their projects and ensure they're used safely and efficiently.

If you're in the roofing industry and looking for high - quality hook blades, we've got you covered. Our Hook Blades for Roofing are made from top - grade materials and designed to meet the highest industry standards. Whether you need a blade for a small residential job or a large commercial project, we have the right solution for you.

If you're interested in learning more about our products or want to start a purchase negotiation, feel free to reach out. We're always happy to help you find the best hook blades for your needs.

References

- "Roofing Tools and Equipment Handbook"

- Industry reports on roofing blade manufacturing and performance standards.