Durability is a crucial factor when it comes to hook blades for shingles. As a supplier of high - quality hook blades for shingles, I have in - depth knowledge about their durability and what it entails. In this blog, I will explore various aspects of the durability of hook blades for shingles, including the factors that affect it, how to measure it, and why it matters in the roofing industry.

Factors Affecting the Durability of Hook Blades for Shingles

Material Quality

The material used to make hook blades plays a fundamental role in determining their durability. High - grade steel is often the preferred choice for hook blades. Stainless steel, for example, offers excellent corrosion resistance. When hook blades are exposed to the elements during roofing projects, they are likely to come into contact with moisture, which can cause rusting. Rust not only weakens the blade but also reduces its cutting efficiency. Our [Hook Blades for Roofing](/hook - blades/hook - blades - for - roofing.html) are crafted from top - quality stainless steel, ensuring that they can withstand the harsh environmental conditions typically encountered on roofing sites.

Carbon steel is another material commonly used. It is known for its high strength and sharpness. However, carbon steel is more prone to corrosion compared to stainless steel. To enhance its durability, carbon steel hook blades are often coated with anti - rust agents. These coatings act as a protective barrier, preventing moisture from reaching the steel surface and thus reducing the risk of rust.

Blade Design

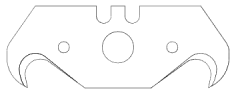

The design of the hook blade also has a significant impact on its durability. A well - designed hook blade has a proper balance between sharpness and strength. For instance, the shape of the hook affects how the blade interacts with the shingles. A hook with the right curvature can cut through shingles more efficiently, reducing the amount of force required. This, in turn, decreases the wear and tear on the blade.

The thickness of the blade is another important design consideration. A thicker blade is generally more durable as it can withstand greater pressure without bending or breaking. Our [Heavy Duty Hook Blades](/hook - blades/heavy - duty - hook - blades.html) are designed with a thicker profile, making them ideal for heavy - duty roofing applications where the blades need to cut through tough shingles.

Usage Conditions

The way hook blades are used and the conditions under which they are used can greatly influence their durability. If hook blades are used to cut through shingles that are extremely thick or hard, they will experience more wear and tear compared to cutting through thinner and softer shingles. Additionally, improper handling of the blades can also reduce their lifespan. For example, using excessive force when cutting or using the blade on inappropriate surfaces can cause the blade to dull or break.

In outdoor roofing projects, exposure to extreme temperatures and weather conditions can also affect the durability of hook blades. High temperatures can cause the metal to expand, while low temperatures can make it brittle. Moisture from rain or humidity can lead to corrosion. Therefore, proper storage and handling of hook blades are essential to maintain their durability.

Measuring the Durability of Hook Blades for Shingles

Cutting Performance Over Time

One of the most practical ways to measure the durability of hook blades is to evaluate their cutting performance over time. A durable hook blade should maintain its sharpness and cutting efficiency for an extended period. This can be measured by counting the number of shingles a blade can cut before it starts to show signs of dullness. A blade that can cut through a large number of shingles without significant loss of sharpness is considered more durable.

Resistance to Wear and Tear

Resistance to wear and tear can be measured by examining the blade's surface after a certain period of use. Signs of wear include chipping, blunting, and deformation of the blade edge. A durable hook blade should show minimal signs of wear even after prolonged use. Microscopic analysis can be used to detect early signs of wear that may not be visible to the naked eye.

Corrosion Resistance

Corrosion resistance is another important aspect of durability. To measure the corrosion resistance of hook blades, they can be subjected to salt spray tests. In these tests, the blades are exposed to a salt - laden mist for a specific period. After the test, the blades are examined for signs of corrosion. A blade with high corrosion resistance will show little or no rust formation.

Why Durability Matters in the Roofing Industry

Cost - Effectiveness

Durable hook blades are more cost - effective in the long run. Although they may have a higher upfront cost compared to less durable blades, they last longer and need to be replaced less frequently. This reduces the overall cost of roofing projects, as contractors do not have to constantly purchase new blades. For roofing contractors, using durable hook blades can significantly improve their profit margins.

Efficiency and Productivity

A durable hook blade maintains its cutting efficiency throughout its lifespan. This means that roofing contractors can work more quickly and effectively. When a blade is sharp and durable, it can cut through shingles with ease, reducing the time and effort required for each cut. This leads to increased productivity on the job site, allowing contractors to complete projects faster and take on more work.

Safety

Durable hook blades are also safer to use. A dull or damaged blade is more likely to slip or break during use, which can pose a significant safety hazard to the user. A blade that maintains its integrity and sharpness reduces the risk of accidents, ensuring the safety of roofing workers.

Our Commitment to Durable Hook Blades

As a supplier of hook blades for shingles, we are committed to providing our customers with the most durable products on the market. Our [Hook Razor Blade](/hook - blades/hook - razor - blade.html) is a prime example of our dedication to quality and durability. We use only the highest - quality materials and state - of - the - art manufacturing processes to ensure that our blades meet the highest standards of durability.

We also conduct rigorous quality control tests on all our products. Each blade is inspected for sharpness, strength, and corrosion resistance before it leaves our factory. This ensures that our customers receive only the best - performing and most durable hook blades.

Conclusion

The durability of hook blades for shingles is a complex yet crucial aspect of the roofing industry. It is affected by factors such as material quality, blade design, and usage conditions. Measuring durability can be done through evaluating cutting performance, resistance to wear and tear, and corrosion resistance. Durable hook blades offer cost - effectiveness, efficiency, productivity, and safety benefits.

If you are in the roofing industry and are looking for high - quality, durable hook blades for shingles, we invite you to contact us for a purchase consultation. We are confident that our products will meet your needs and exceed your expectations.

References

- ASTM International standards on blade materials and testing.

- Industry research on roofing tools and their performance.

- Manufacturer's specifications and product data sheets for hook blades.