When it comes to box cutters, there are various types available in the market. Among them, the Hook Blade Box Cutter and the regular box cutter stand out as two distinct tools, each with its own set of features, advantages, and ideal use - cases. As a supplier of Hook Blade Box Cutters, I am well - versed in the differences between these two types of cutters, and I'm excited to share this knowledge with you.

Design and Structure

One of the most obvious differences between a Hook Blade Box Cutter and a regular box cutter lies in their blade design. A regular box cutter typically features a straight blade. This straight blade is usually retractable, which means it can be pulled in and out of the cutter's body for safety and convenience. The blade is often sharp on one or both edges and comes in a variety of lengths and thicknesses, depending on the specific model and intended use.

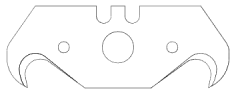

On the other hand, a Hook Blade Box Cutter has a uniquely shaped blade that resembles a hook. The hook shape gives the blade a distinct cutting edge that is not found in regular box cutters. The curvature of the hook blade allows for different types of cutting actions. The blade of a Hook Blade Box Cutter may also be retractable, but its hook design is the defining characteristic that sets it apart from the traditional straight - bladed box cutter.

Cutting Action

The cutting action of these two types of box cutters is also quite different. A regular box cutter is designed for straightforward, linear cuts. You can use it to slice through cardboard boxes, open plastic packaging, or cut through thin materials with a simple, back - and - forth motion. The straight blade provides a clean, precise cut when used correctly, making it ideal for tasks where accuracy and a straight cut line are essential.

In contrast, the hook blade of a Hook Blade Box Cutter offers a more versatile cutting action. The hook shape allows for both pulling and pushing cuts. When you pull the hook blade towards you, the curved edge can easily catch and cut through materials. This is particularly useful for tasks such as cutting through ropes, cables, or for making quick work of thick or tough materials. The hook blade can also be used to make curved cuts, which is a feature not commonly found in regular box cutters. For example, if you need to cut a circular shape out of a piece of cardboard, the hook blade can be maneuvered to follow the curve more easily.

Safety Features

Both types of box cutters come with safety features, but they are implemented differently. Regular box cutters often rely on a retractable blade mechanism. When the blade is not in use, it can be pushed back into the cutter's body, reducing the risk of accidental cuts. Some regular box cutters also have a locking mechanism to keep the blade in the retracted position.

Hook Blade Box Cutters also have safety features. Many models come with a retractable blade as well. However, due to the unique hook shape, additional safety considerations are often built in. For instance, some Hook Blade Box Cutters have a blade guard that can be adjusted to cover the hook blade when not in use. This helps prevent the sharp hook from causing injuries during storage or transportation.

Applications

The applications of these two types of box cutters vary based on their design and cutting capabilities. Regular box cutters are a staple in offices, warehouses, and retail stores. They are perfect for everyday tasks such as opening shipping boxes, cutting tape, and trimming paper. Their simplicity and precision make them a go - to tool for general - purpose cutting jobs.

Hook Blade Box Cutters, on the other hand, are more specialized. They are commonly used in industries such as roofing, construction, and packaging. In the roofing industry, Hook Blades for Roofing are used to cut through roofing materials like shingles, felt paper, and rubber membranes. The hook blade can easily catch and cut through these materials, making the installation and repair process more efficient. In construction, Hook Blade Box Cutters can be used to cut through insulation materials, ropes, and cables. In the packaging industry, they can be used to open large or heavy - duty packages that regular box cutters may struggle with.

Blade Types and Durability

The blade types used in these two cutters also differ. Regular box cutters usually use standard straight blades that are made from high - carbon steel or other durable materials. These blades are designed to stay sharp for a reasonable amount of time and can be easily replaced when they become dull.

Hook Blade Box Cutters use specialized hook - shaped blades. There are different types of hook blades available, such as Hook Razor Blade and Heavy Duty Hook Blades. Hook Razor Blades are extremely sharp and are suitable for precise cutting tasks. Heavy Duty Hook Blades, on the other hand, are designed to withstand more pressure and are used for cutting through tough materials. These blades are often made from high - quality alloys or have special coatings to enhance their durability and resistance to wear.

Ergonomics

Ergonomics is an important factor when it comes to using any tool. Regular box cutters are typically designed with a simple, lightweight body that is easy to hold and maneuver. They often have a comfortable grip that allows for extended use without causing too much fatigue.

Hook Blade Box Cutters may have a slightly different ergonomic design. Due to the unique shape of the hook blade, the handle of a Hook Blade Box Cutter may be designed to provide better control during the pulling and pushing cutting motions. Some Hook Blade Box Cutters have a contoured handle that fits comfortably in the hand, reducing the strain on the user's fingers and wrist, especially when performing repetitive cutting tasks.

Cost

In general, the cost of a Hook Blade Box Cutter and a regular box cutter can vary. Regular box cutters are widely available and are often more affordable, especially the basic models. They are mass - produced, and the cost of manufacturing the straight blades is relatively low.

Hook Blade Box Cutters, however, are more specialized tools. The cost of manufacturing the unique hook - shaped blades and the additional safety features can make them more expensive than regular box cutters. However, considering their specialized applications and the efficiency they bring to certain tasks, the investment in a Hook Blade Box Cutter can be well worth it for businesses or individuals who need to perform specific cutting jobs on a regular basis.

Why Choose a Hook Blade Box Cutter from Our Supply?

As a supplier of Hook Blade Box Cutters, we offer high - quality products that are designed to meet the needs of various industries. Our Hook Blade Box Cutters are made with precision and are equipped with the latest safety features. We have a wide range of hook blades available, including Hook Razor Blades and Heavy Duty Hook Blades, to ensure that you can find the right tool for your specific cutting requirements.

If you are in the roofing, construction, or packaging industry, or if you simply need a more versatile cutting tool for your everyday tasks, our Hook Blade Box Cutters are an excellent choice. We are committed to providing our customers with the best products and services. Whether you are a small business or a large corporation, we can work with you to meet your procurement needs.

If you are interested in learning more about our Hook Blade Box Cutters or would like to discuss a potential purchase, please feel free to reach out to us. We are always happy to have a conversation and help you find the perfect cutting solution for your business.

References

- "Hand Tools: A Comprehensive Guide", Industrial Tool Publishing, 2020

- "Cutting Tools in the Construction Industry", Construction Tools Journal, 2021

- "Advances in Blade Technology", Blade Research Institute, 2019