When it comes to roofing projects, the choice of tools can significantly impact both the quality of the work and the overall cost. Among the essential tools in a roofer's arsenal, hook blades stand out for their unique functionality and versatility. As a supplier of Hook Blades for Roofing, I have witnessed firsthand the cost - effectiveness of these tools in various roofing applications. In this blog, we will explore what makes hook blades a cost - effective choice for roofing projects.

Understanding Hook Blades for Roofing

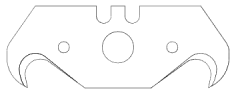

Hook blades are specialized cutting tools designed with a distinct hooked shape. This shape allows for precise and efficient cutting in tight spaces, around corners, and along edges, which are common scenarios in roofing work. They are available in different sizes and configurations, such as Hook Blade Box Cutter and Heavy Duty Hook Blades, to meet the diverse needs of roofing professionals.

Initial Investment vs. Long - Term Savings

The initial cost of hook blades may seem higher compared to some other basic cutting tools. However, when considering the long - term savings, they prove to be a cost - effective investment. High - quality hook blades are made from durable materials that can withstand the rigors of roofing work. They have a longer lifespan than cheaper, lower - quality blades, which means fewer replacements over time. For example, a Heavy Duty Hook Blade made from premium steel can last through multiple roofing projects, reducing the need to constantly purchase new blades.

Increased Productivity

One of the most significant ways hook blades contribute to cost - effectiveness is by increasing productivity. The unique hooked design enables roofers to make quick and accurate cuts without having to reposition the tool constantly. This saves time, especially on large roofing projects where every minute counts. Faster work means that roofers can take on more projects in a given period, increasing their overall revenue. Additionally, the precision cutting provided by hook blades reduces the likelihood of mistakes, such as over - cutting or uneven cuts, which can lead to costly rework.

Reduced Labor Costs

Since hook blades allow for faster and more efficient cutting, they can also lead to reduced labor costs. Roofing projects often involve a significant amount of labor, and any tool that can streamline the process can have a positive impact on the bottom line. With hook blades, roofers can complete tasks more quickly, which may require fewer man - hours to finish a project. This is particularly beneficial for contractors who are working on a tight budget or a fixed - price contract.

Compatibility and Versatility

Hook blades are highly versatile and can be used in a variety of roofing materials, including asphalt shingles, rubber membranes, and metal sheets. This versatility means that roofers do not need to invest in multiple types of cutting tools for different materials. A single set of hook blades, such as Hook Blades for Roofing, can handle a wide range of roofing applications, providing cost - savings in terms of tool procurement.

Safety and Cost - Effectiveness

Safety is another important aspect of cost - effectiveness in roofing. Hook blades are designed with safety features in mind. Their ergonomic handles provide a comfortable grip, reducing the risk of hand fatigue and injuries. By preventing accidents and injuries on the job site, hook blades can help avoid costly medical expenses, worker compensation claims, and project delays. A safe work environment also leads to higher employee morale and productivity, which further contributes to the overall cost - effectiveness of using hook blades.

Case Studies: Real - World Cost - Effectiveness

Let's look at some real - world examples to illustrate the cost - effectiveness of hook blades. A roofing contractor was working on a large residential roofing project. Initially, they were using traditional box cutters, which were slow and required frequent blade changes. After switching to Hook Blade Box Cutters, they noticed a significant improvement in productivity. They were able to complete the project 20% faster than expected, which not only saved on labor costs but also allowed them to take on another project within the same time frame.

Another case involved a commercial roofing project with a complex design that required a lot of precise cutting around edges and corners. The use of Heavy Duty Hook Blades enabled the roofing team to make accurate cuts quickly, reducing the amount of rework. As a result, they were able to finish the project on time and within budget, despite the challenging nature of the work.

Maintenance and Cost - Effectiveness

Proper maintenance of hook blades can also contribute to their cost - effectiveness. Regular cleaning and sharpening can extend the lifespan of the blades, reducing the frequency of replacements. Most hook blades are designed to be easily maintained, and simple maintenance tasks can be performed on - site by the roofers themselves. This means that there is no need to send the blades to a professional for maintenance, which can save both time and money.

Conclusion

In conclusion, the cost - effectiveness of hook blades for roofing is evident when considering the initial investment, long - term savings, increased productivity, reduced labor costs, versatility, safety, and maintenance. As a supplier of Hook Blades for Roofing, I encourage roofing professionals to consider the benefits of these tools in their projects. Whether you are a small - scale roofer or a large - scale contractor, hook blades can help you improve the quality of your work while reducing costs.

If you are interested in learning more about our hook blades or would like to discuss a potential purchase, please feel free to reach out. We are always ready to assist you in finding the right hook blades for your roofing needs.

References

- "Roofing Tools and Equipment: A Comprehensive Guide" - Industry - specific handbook on roofing tools

- "Cost - Benefit Analysis of Specialized Cutting Tools in Construction" - Academic research on the cost - effectiveness of construction tools

- Case studies from roofing contractors using hook blades in their projects