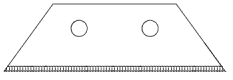

As a supplier of trapezoid blades, I've had the privilege of closely observing these essential cutting tools in various industrial applications. Trapezoid blades are widely used across multiple sectors, including manufacturing, packaging, and food processing, due to their unique shape and cutting capabilities. However, like any other product, they are not without their common defects. Understanding these issues is crucial for both suppliers and users to ensure optimal performance and cost - effectiveness.

1. Uneven Edge Wear

One of the most prevalent defects in trapezoid blades is uneven edge wear. This occurs when the blade's cutting edge does not wear uniformly during use. Several factors can contribute to this problem. Firstly, improper mounting of the blade can lead to uneven pressure distribution. If the blade is not installed correctly on the cutting machine, certain parts of the edge will bear more stress than others, causing accelerated wear in those areas.

Secondly, the nature of the material being cut also plays a significant role. For instance, if the material has inconsistent hardness or density, the blade will experience different levels of resistance as it cuts through. This can result in uneven wear patterns. When cutting materials with hard inclusions, the blade may wear more rapidly at the points where it encounters these inclusions.

The consequences of uneven edge wear are substantial. It reduces the blade's cutting efficiency, as the uneven edge cannot make a clean and precise cut. This can lead to jagged edges on the cut material, which is unacceptable in many applications, especially in industries where precision is critical, such as electronics manufacturing. Moreover, uneven wear shortens the blade's lifespan, increasing the frequency of blade replacements and thus raising operational costs.

2. Chipping and Cracking

Chipping and cracking are another common set of defects in trapezoid blades. Chipping refers to the small pieces of the blade's cutting edge breaking off, while cracking involves the formation of cracks on the blade surface. These defects can be caused by a variety of factors.

High - impact forces during cutting are a major culprit. When the blade is used to cut through tough or fibrous materials, it may be subjected to sudden and intense forces. If the blade's material is not strong enough to withstand these forces, chipping or cracking can occur. For example, in the woodworking industry, when cutting hardwoods, the blade may experience significant stress, leading to these defects.

In addition, improper heat treatment during the blade manufacturing process can also contribute to chipping and cracking. If the blade is not heat - treated correctly, its internal structure may be weakened, making it more prone to damage under normal cutting conditions.

Chipping and cracking have serious implications for the blade's performance. A chipped or cracked blade cannot cut effectively, as the damaged areas disrupt the cutting edge. This can lead to increased cutting forces, which in turn can cause more damage to the blade and the cutting machine. It also poses a safety risk, as the broken pieces can fly off during operation, potentially injuring workers.

3. Dullness

Dullness is a defect that all blade users are familiar with. A dull trapezoid blade loses its ability to make sharp and clean cuts. There are several reasons for a blade to become dull.

Continuous use is the most obvious cause. Over time, the cutting edge of the blade gradually wears down, becoming less sharp. The rate of dulling depends on the frequency and intensity of use. For example, in a high - volume production environment where the blade is in constant operation, it will dull more quickly.

The type of material being cut also affects the blade's dullness. Cutting abrasive materials, such as glass fibers or certain plastics, can accelerate the dulling process. These materials have a high level of abrasiveness, which wears away the blade's cutting edge at a faster rate.

A dull blade not only reduces cutting quality but also increases energy consumption. As the blade becomes dull, more force is required to make a cut, which means the cutting machine has to work harder. This leads to higher energy costs and can also cause premature wear on the machine's components.

4. Corrosion

Corrosion is a defect that is particularly relevant for trapezoid blades used in certain environments. When the blade is exposed to moisture, chemicals, or other corrosive substances, its surface can start to corrode.

In the food processing industry, for example, blades are often in contact with water, acids, and salts. These substances can react with the blade's metal surface, causing corrosion. Similarly, in the chemical industry, where blades may be used to cut through chemical - containing materials, corrosion is a common problem.

Corrosion weakens the blade's structure, making it more prone to other defects such as chipping and cracking. It also affects the blade's cutting performance, as the corroded surface is rough and uneven. This can lead to poor cutting quality and increased friction during cutting.

Solutions and Recommendations

To address these common defects, several measures can be taken. For uneven edge wear, proper blade installation is essential. Operators should follow the manufacturer's instructions carefully to ensure the blade is mounted correctly. Additionally, selecting the right blade for the specific material being cut can help reduce uneven wear.

To prevent chipping and cracking, blades should be made from high - quality materials with sufficient strength and toughness. Proper heat treatment during manufacturing is also crucial. During use, operators should avoid subjecting the blade to excessive impact forces.

To combat dullness, regular blade sharpening is necessary. This can extend the blade's lifespan and maintain its cutting performance. Using blade coatings can also help reduce the rate of dulling, especially when cutting abrasive materials.

For corrosion, blades can be coated with anti - corrosion materials. In environments where corrosion is a significant concern, stainless steel blades may be a better choice.

At our company, we offer a wide range of high - quality trapezoid blades, including Allfit Trapezoid Blades, Trapezoidal Shaped Blades With One - sided Waved Grinding, and 2 Notch Utility Trapezoide Blades. Our blades are manufactured using advanced techniques and high - quality materials to minimize the occurrence of these common defects.

If you are interested in purchasing trapezoid blades or have any questions about our products, please feel free to contact us for a detailed discussion. We are committed to providing you with the best - quality blades and excellent customer service.

References

- "Cutting Tool Technology" by John A. Schey

- "Handbook of Machining with Cutting Tools" by Peter K. Wright and David A. Campbell

- Industry reports on trapezoid blade applications and performance in various sectors.