Hey there! As a supplier of trapezoid blades, I get a ton of questions from folks like you about how to pick the right ones for your specific needs. It can be a bit of a head - scratcher, but don't worry, I'm here to break it down for you.

Understanding Your Work Requirements

First things first, you've got to figure out what kind of work you'll be using the trapezoid blades for. Are you in the woodworking industry, cutting through different types of wood? Maybe you're into metalworking, slicing through sheets of steel or aluminum. Or perhaps you're involved in the paper or fabric industry, where precision cutting is key.

If you're working with wood, you'll need a blade that can handle the density and grain of the wood. Hardwoods like oak or maple are tougher to cut through than softwoods like pine. A blade with a sharp edge and the right tooth configuration will make your job a whole lot easier. For instance, if you're making straight cuts in softwood, a blade with fewer teeth per inch might be sufficient. But for more intricate cuts or working with hardwood, you'll want a blade with more teeth for a smoother finish.

In metalworking, the hardness of the metal is the main factor. Stainless steel is much harder than mild steel, so you'll need a blade designed to cut through tough materials. High - speed steel (HSS) or carbide - tipped blades are often the go - to choices for metal cutting. They can withstand the heat and friction generated during the cutting process without losing their edge quickly.

When it comes to paper or fabric cutting, precision is everything. You need a blade that can make clean, sharp cuts without tearing or fraying the material. Blades with a fine edge and a smooth cutting action are ideal for these applications.

Blade Size and Shape

The size and shape of the trapezoid blade also play a crucial role in its performance. The length of the blade determines how deep of a cut you can make. If you're working on thick materials, you'll need a longer blade. But keep in mind that longer blades might be more prone to bending or vibrating, so you'll need to make sure your cutting equipment can handle them properly.

The width of the blade affects the stability of the cut. A wider blade is generally more stable, but it might also be more difficult to maneuver in tight spaces. You've got to find the right balance between stability and maneuverability based on your specific cutting tasks.

As for the shape of the trapezoid blade, different shapes are designed for different purposes. Some trapezoid blades have a straight edge, which is great for making straight cuts. Others have a curved or angled edge, which can be useful for making beveled cuts or creating unique shapes. For example, the Trapezoidal Shaped Blades With One - sided Waved Grinding are designed to provide a special cutting effect, which can be very handy in certain applications.

Tooth Configuration

The tooth configuration of a trapezoid blade is another important aspect to consider. The number of teeth per inch (TPI) affects the cutting speed and the finish of the cut. A blade with a high TPI will make a smoother cut but will cut more slowly. On the other hand, a blade with a low TPI will cut faster but might leave a rougher finish.

The shape of the teeth also matters. There are different tooth shapes, such as square, hook, and skip teeth. Square teeth are great for making cross - cuts in wood, while hook teeth are better for ripping cuts (cuts along the grain of the wood). Skip teeth are often used for cutting soft materials or materials with a lot of chips, as they allow the chips to be removed more easily.

Coating and Material

The material of the blade and any coatings it has can significantly impact its performance and lifespan. As mentioned earlier, high - speed steel (HSS) and carbide - tipped blades are popular choices for metal cutting. HSS blades are relatively inexpensive and can handle a wide range of cutting tasks. Carbide - tipped blades, on the other hand, are more expensive but offer superior cutting performance and a longer lifespan, especially when cutting hard materials.

For woodworking, carbon steel blades are a common option. They're affordable and can provide a good cutting edge. However, they might require more frequent sharpening compared to blades made from other materials.

Some blades come with special coatings, such as titanium nitride (TiN) or black oxide. These coatings can reduce friction, prevent corrosion, and extend the life of the blade. For example, a TiN - coated blade will stay sharp longer and cut more smoothly, especially in high - heat cutting applications.

Compatibility with Your Equipment

It's essential to make sure the trapezoid blade you choose is compatible with your cutting equipment. Different machines have different blade mounting systems, so you need to select a blade that fits properly. Using an incompatible blade can not only affect the performance of the blade but also pose a safety risk.

Check the specifications of your cutting machine, including the arbor size (the shaft on which the blade is mounted), the maximum blade diameter it can accommodate, and the type of blade mounting system. If you're not sure, consult the manufacturer's manual or contact the manufacturer directly for guidance.

Specific Blade Recommendations

Now, let me give you a few specific blade recommendations based on different applications.

If you're looking for a versatile blade for general woodworking tasks, the Allfit Trapezoid Blades are a great choice. They come in different sizes and tooth configurations, so you can find the one that suits your needs. Whether you're making straight cuts, cross - cuts, or beveled cuts, these blades can get the job done.

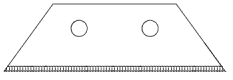

For utility cutting tasks, such as cutting cardboard, plastic, or thin metal sheets, the 2 Notch Utility Trapezoide Blades are ideal. They have a sharp edge and a unique notch design that allows for easy cutting and handling.

Conclusion

Choosing the right trapezoid blades for your needs doesn't have to be a daunting task. By understanding your work requirements, considering the blade size, shape, tooth configuration, material, and compatibility with your equipment, you can make an informed decision.

If you're still not sure which trapezoid blade is right for you, don't hesitate to reach out. As a supplier, I'm here to help you find the perfect blade for your specific applications. We can discuss your needs in detail and recommend the best options available. So, let's get in touch and start working towards getting you the right trapezoid blades for your projects!

References

- Woodworking Machinery and Equipment Handbook

- Metal Cutting Technology: Principles and Practice

- Cutting Tools and Their Application by Sandvik Coromant