Hey there! As a supplier of trapezoidal shaped blades, I've been getting a lot of questions lately about how these unique blades affect the surface finish of the cut material. So, I thought I'd take a deep dive into this topic and share some insights with you all.

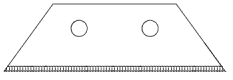

First off, let's talk about what makes trapezoidal shaped blades different. Unlike traditional rectangular or circular blades, trapezoidal blades have a distinct shape with non - parallel sides. This shape gives them some special properties that can have a significant impact on the cutting process and the resulting surface finish.

One of the key advantages of trapezoidal shaped blades is their ability to provide a more consistent cut. The tapered shape allows the blade to gradually penetrate the material, reducing the amount of force required at the start of the cut. This is particularly useful when cutting materials that are prone to chipping or cracking, like certain types of plastics or brittle metals. When the blade enters the material smoothly, it's less likely to cause damage to the surface, resulting in a cleaner and more even finish.

For example, if you're using a Standard Trapezoid Blades Extra Wide to cut a thin plastic sheet, the trapezoidal shape helps to prevent the edges from fraying or breaking. The blade's design distributes the cutting force evenly across the width of the blade, which minimizes the stress on the material and keeps the surface intact.

Another aspect to consider is the cutting angle. Trapezoidal blades can be designed with different cutting angles depending on the application. A steeper cutting angle might be used for harder materials, as it allows the blade to dig in more effectively. On the other hand, a shallower angle is better for softer materials, as it provides a more gentle cut. This flexibility in cutting angles gives you more control over the surface finish.

Let's say you're working with a soft rubber material. Using a Trapezoid Blades for Utility Knives with a shallower cutting angle can prevent the rubber from getting torn or stretched during the cutting process. The blade glides through the material smoothly, leaving a nice, clean surface.

The sharpness of the blade also plays a crucial role in the surface finish. Trapezoidal shaped blades can be sharpened to a very fine edge, which is essential for achieving a high - quality cut. A sharp blade cuts through the material more cleanly, leaving less debris and fewer imperfections on the surface.

Our Trapezoidal Shaped Blades With One - sided Waved Grinding are a great example of this. The one - sided waved grinding enhances the blade's sharpness and cutting performance. When you use these blades, you'll notice a significant improvement in the surface finish of the cut material. The waves on the blade help to break up the material in a more controlled way, reducing the chances of rough edges or burrs.

However, it's not just about the blade itself. The way you use the blade also affects the surface finish. For instance, the speed at which you cut can make a big difference. Cutting too fast can cause the blade to vibrate, which can lead to an uneven surface finish. On the other hand, cutting too slowly might cause the material to heat up, especially if it's a thermoplastic. This can result in melting or warping of the material, ruining the surface finish.

The pressure you apply while cutting is another important factor. Applying too much pressure can cause the blade to dig in too deeply, leaving a rough and uneven surface. It's important to find the right balance of pressure to ensure a smooth and consistent cut.

In addition to these factors, the type of material you're cutting matters a lot. Different materials have different properties, and trapezoidal shaped blades might perform differently depending on the material. For example, when cutting wood, the trapezoidal blade's shape can help to follow the grain of the wood more easily, resulting in a cleaner cut along the grain lines. But when cutting metal, the blade's ability to handle high - pressure cutting and resist wear comes into play.

Now, if you're in the market for trapezoidal shaped blades, you're probably wondering how to choose the right ones for your specific application. Well, the first step is to consider the material you'll be cutting. As we've discussed, different materials require different blade properties, such as cutting angle and sharpness. You should also think about the thickness of the material. Thicker materials might need a more robust blade, while thinner materials can be cut with a more delicate one.

The size of the blade is another factor. A larger blade might be more suitable for cutting large sheets of material, while a smaller blade could be better for precision cutting. And of course, you'll want to consider the quality of the blade. High - quality blades are made from better materials and have better manufacturing processes, which means they'll last longer and provide a better surface finish.

As a supplier of trapezoidal shaped blades, I can tell you that we've spent a lot of time researching and developing our blades to ensure they meet the highest standards. We understand that getting the right surface finish is crucial for your projects, whether you're in the manufacturing industry, a DIY enthusiast, or a professional craftsman.

If you're interested in learning more about our trapezoidal shaped blades or have any questions about how they can improve the surface finish of your cut materials, don't hesitate to reach out. We're here to help you find the perfect blades for your needs. Whether you're looking for Standard Trapezoid Blades Extra Wide, Trapezoid Blades for Utility Knives, or Trapezoidal Shaped Blades With One - sided Waved Grinding, we've got you covered.

We're always happy to have a chat about your specific requirements and provide you with expert advice. Whether you're a small - scale operation or a large manufacturing plant, we can work with you to find the best blade solutions. So, if you're ready to take your cutting projects to the next level and achieve a top - notch surface finish, get in touch with us.

In conclusion, trapezoidal shaped blades offer a lot of benefits when it comes to the surface finish of the cut material. Their unique shape, cutting angles, and sharpness all contribute to a cleaner, more even, and high - quality cut. By choosing the right blade for your application and using it correctly, you can ensure that your cutting projects turn out just the way you want them to.

References

- "The Science of Cutting Tools" - A comprehensive guide on cutting tool design and performance.

- "Materials and Their Properties" - A book that delves into the characteristics of different materials and how they interact with cutting tools.