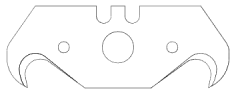

As a seasoned supplier of Hook Blades for Shingles, I understand the significance of choosing the right handle for these essential tools. The handle plays a crucial role in the overall performance, comfort, and safety of using hook blades for shingles. In this blog post, I will share my insights on how to make an informed decision when selecting the appropriate handle for hook blades, ensuring that you get the most out of your roofing projects.

Understanding the Importance of the Handle

Before delving into the selection process, it's essential to understand why the handle is so important. The handle of a hook blade for shingles is the interface between the user and the tool. It directly affects how the blade is controlled, how much force can be applied, and how comfortable the user feels during extended periods of use. A well-designed handle can enhance efficiency, reduce fatigue, and minimize the risk of injuries.

Factors to Consider When Choosing a Handle

Ergonomics

One of the most critical factors to consider when choosing a handle for hook blades is ergonomics. An ergonomic handle is designed to fit comfortably in the hand, reducing strain and fatigue. Look for handles that have a contoured shape, with a grip that conforms to the natural curvature of your hand. This will ensure that you can maintain a secure hold on the blade without having to exert excessive force.

Additionally, consider the size of the handle. It should be large enough to provide a comfortable grip but not so large that it becomes cumbersome to use. Handles that are too small can cause your hand to cramp, while those that are too large can make it difficult to control the blade accurately.

Material

The material of the handle also plays a significant role in its performance and durability. There are several materials commonly used for hook blade handles, each with its own advantages and disadvantages.

- Wood: Wooden handles are a classic choice for many tools, including hook blades for shingles. They are comfortable to hold, provide a natural grip, and are relatively lightweight. However, wood can be prone to warping, splitting, and rotting if not properly maintained.

- Plastic: Plastic handles are lightweight, durable, and resistant to moisture and chemicals. They are also often more affordable than other materials. However, some plastic handles may not provide the same level of comfort or grip as wood or rubber.

- Rubber: Rubber handles are known for their excellent grip and shock absorption. They are also resistant to moisture and chemicals, making them a good choice for use in wet or dirty conditions. However, rubber handles can be more expensive than other materials and may wear out over time.

Weight

The weight of the handle can also affect the overall balance and performance of the hook blade. A handle that is too heavy can make the blade feel cumbersome and difficult to maneuver, while a handle that is too light may not provide enough stability. Look for a handle that has a balanced weight distribution, with the weight evenly distributed between the handle and the blade.

Grip Texture

The texture of the grip is another important consideration. A handle with a smooth surface may be slippery, especially when your hands are wet or sweaty. Look for handles that have a textured grip, such as a rubberized coating or a series of ridges or bumps. This will provide a better grip and help prevent the blade from slipping out of your hand.

Compatibility

Finally, make sure that the handle you choose is compatible with the hook blade you are using. Some handles are designed to fit specific types or sizes of blades, so it's important to check the manufacturer's specifications before making a purchase. Using an incompatible handle can affect the performance of the blade and may even pose a safety risk.

Different Types of Handles for Hook Blades

There are several different types of handles available for hook blades for shingles, each with its own unique features and benefits. Here are some of the most common types:

Straight Handles

Straight handles are the most basic type of handle for hook blades. They are simple, lightweight, and easy to use. Straight handles are typically used for general-purpose roofing tasks, such as cutting shingles or removing old roofing materials.

Offset Handles

Offset handles are designed to provide better visibility and access to hard-to-reach areas. They are angled away from the blade, allowing you to see what you are cutting without having to move your hand out of the way. Offset handles are often used for more precise cutting tasks, such as trimming shingles around vents or chimneys.

T-Handles

T-handles are shaped like the letter "T" and provide a comfortable and secure grip. They are typically used for heavy-duty roofing tasks, such as removing large sections of old roofing materials. T-handles are also useful for applying more force when cutting through thick or stubborn shingles.

Conclusion

Choosing the right handle for hook blades for shingles is an important decision that can have a significant impact on the performance, comfort, and safety of your roofing projects. By considering factors such as ergonomics, material, weight, grip texture, and compatibility, you can select a handle that meets your specific needs and preferences.

At [Our Company], we offer a wide range of high-quality Hook Blades for Shingles with various handle options to suit your needs. Whether you are a professional roofer or a DIY enthusiast, we have the tools you need to get the job done right.

If you have any questions or need further assistance in choosing the right handle for your hook blade, please don't hesitate to [Contact Us]. Our team of experts is always available to help you make an informed decision and ensure that you get the most out of your roofing tools.