Hey there! As a supplier of Hook Blades for Roofing, I'm super stoked to share with you how these nifty tools work. Roofing is no easy feat, and having the right tools can make all the difference. So, let's dive right in and explore the ins and outs of hook blades for roofing.

What Are Hook Blades for Roofing?

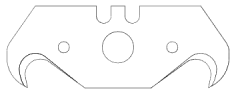

First things first, what exactly are hook blades for roofing? Well, they're specialized cutting tools designed specifically for roofing tasks. Unlike regular blades, hook blades have a unique curved shape that makes them perfect for slicing through roofing materials like shingles, membranes, and underlayment. The hook design allows for precise cuts, even in tight spaces, and gives you better control over the cutting process.

How Do They Work?

Let's break down the process of how hook blades for roofing work. When you're working on a roof, you'll typically start by preparing the area. This might involve removing old roofing materials, cleaning the surface, and laying down a new underlayment. Once the area is ready, it's time to start cutting.

Cutting Shingles

Shingles are one of the most common roofing materials, and hook blades are great for cutting them to size. To cut shingles, you'll need to mark the cutting line using a straightedge or a chalk line. Then, place the hook blade at the starting point of the cut, with the curved part of the blade facing down. Apply gentle pressure and pull the blade towards you, following the marked line. The hook blade will slice through the shingle cleanly and smoothly, leaving a straight edge.

Cutting Membranes and Underlayment

Membranes and underlayment are used to provide an extra layer of protection for the roof. They're typically made of materials like asphalt, rubber, or synthetic polymers, and they can be a bit tricky to cut. However, hook blades are up to the task. To cut membranes and underlayment, you'll need to use a similar technique as cutting shingles. Mark the cutting line, place the hook blade at the starting point, and pull the blade towards you. The hook blade will cut through the material without tearing or fraying it.

Cutting in Tight Spaces

One of the biggest advantages of hook blades for roofing is their ability to cut in tight spaces. For example, when you're working around vents, pipes, or other obstacles on the roof, it can be difficult to use a regular blade. However, the curved shape of the hook blade allows you to get into those tight spaces and make precise cuts. You can also use the hook blade to trim the edges of the roofing material to fit around the obstacles.

Types of Hook Blades for Roofing

There are several types of hook blades for roofing available on the market, each with its own unique features and benefits. Here are some of the most common types:

Hook Blade Box Cutter

A hook blade box cutter is a versatile tool that can be used for a variety of roofing tasks. It typically has a retractable blade that can be adjusted to different lengths, making it easy to cut through different thicknesses of roofing material. The box cutter design also makes it easy to hold and control, even when you're working on a sloped roof.

Hook Blades for Roofing

These are the standard hook blades that are specifically designed for roofing work. They come in different sizes and shapes, depending on the type of roofing material you're working with. Some hook blades have a serrated edge, which can be useful for cutting through tough materials like rubber or synthetic membranes.

Heavy Duty Hook Blades

If you're working with thick or heavy roofing materials, you'll need a heavy-duty hook blade. These blades are made from high-quality steel and are designed to withstand the rigors of heavy use. They have a thicker blade and a stronger cutting edge, which makes them ideal for cutting through materials like asphalt shingles, metal roofing, and fiberglass insulation.

Tips for Using Hook Blades for Roofing

Here are some tips to help you get the most out of your hook blades for roofing:

- Choose the Right Blade: Make sure you choose the right blade for the type of roofing material you're working with. Using the wrong blade can result in a poor cut and may even damage the blade.

- Keep the Blade Sharp: A sharp blade will make your cutting job easier and more efficient. Make sure you replace the blade regularly to keep it sharp.

- Use the Right Technique: When using a hook blade, make sure you use the right technique. Apply gentle pressure and pull the blade towards you, following the marked line. Don't push the blade, as this can cause it to skip or tear the material.

- Wear Protective Gear: When working on a roof, it's important to wear protective gear, such as gloves, safety glasses, and a hard hat. This will help protect you from injuries.

Why Choose Our Hook Blades for Roofing?

As a supplier of Hook Blades for Roofing, we take pride in offering high-quality products that are designed to meet the needs of our customers. Here are some reasons why you should choose our hook blades:

- Quality Materials: Our hook blades are made from high-quality steel, which ensures durability and long-lasting performance.

- Sharp Cutting Edge: Our blades have a sharp cutting edge that makes it easy to cut through roofing materials.

- Versatile Design: Our hook blades come in different sizes and shapes, which makes them suitable for a variety of roofing tasks.

- Competitive Pricing: We offer our hook blades at competitive prices, which makes them an affordable option for roofing contractors and DIY enthusiasts.

Contact Us for Procurement

If you're interested in purchasing our Hook Blades for Roofing, we'd love to hear from you. Whether you're a professional roofing contractor or a DIY enthusiast, we have the right hook blades for your needs. Contact us today to discuss your requirements and get a quote. We're always happy to help you find the best solution for your roofing project.

References

- Smith, J. (2020). The Complete Guide to Roofing Tools. Roofing Magazine.

- Johnson, A. (2019). How to Choose the Right Hook Blade for Your Roofing Project. DIY Roofing Blog.