When it comes to heavy - duty cutting tasks, one question that often arises among professionals and DIY enthusiasts alike is: "Do heavy duty hook blades have a smooth cutting action?" As a supplier of Heavy Duty Hook Blades, I've delved deep into this topic to provide you with a comprehensive answer.

Understanding Heavy Duty Hook Blades

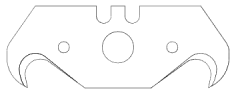

Heavy Duty Hook Blades are specialized cutting tools designed for tough materials and demanding applications. They are characterized by their unique hook - shaped design, which offers several advantages over traditional straight blades. These blades are commonly used in industries such as roofing, construction, and manufacturing, where they are required to cut through materials like roofing membranes, asphalt shingles, and thick plastics.

The hook shape of these blades provides a better grip on the material being cut, allowing for more precise and controlled cuts. This design also helps to prevent the blade from slipping off the material, which is especially important when working with slippery or flexible materials.

Factors Affecting the Cutting Action

To determine whether heavy duty hook blades have a smooth cutting action, we need to consider several factors:

Blade Material

The material of the blade plays a crucial role in its cutting performance. High - quality heavy duty hook blades are typically made from premium steel alloys that offer excellent hardness and sharpness. For example, blades made from high - carbon steel or stainless steel are known for their durability and ability to maintain a sharp edge for an extended period. These materials can cut through tough materials with less resistance, resulting in a smoother cutting action.

Blade Sharpness

A sharp blade is essential for a smooth cutting action. Dull blades tend to tear and snag the material, rather than making a clean cut. Heavy duty hook blades are often precision - ground to ensure a sharp cutting edge. Regular sharpening or blade replacement is necessary to maintain the blade's sharpness. When the blade is sharp, it can glide through the material easily, reducing the amount of force required and minimizing the risk of uneven cuts.

Cutting Angle

The cutting angle of the hook blade also affects its cutting performance. The optimal cutting angle depends on the type of material being cut. For softer materials, a shallower cutting angle may be sufficient, while harder materials may require a steeper angle. A well - designed heavy duty hook blade will have a cutting angle that is optimized for a wide range of materials, allowing for a smooth cutting action across different applications.

Material Compatibility

Not all heavy duty hook blades are suitable for every type of material. Using the wrong blade for a particular material can result in a poor cutting action. For example, a blade designed for cutting roofing materials may not perform well when used on thick plastics. It's important to choose a blade that is specifically designed for the material you are working with. When the blade is compatible with the material, it can cut through it smoothly, without causing excessive wear or damage to the blade.

Real - World Applications and Smooth Cutting Action

Let's take a look at some real - world applications where heavy duty hook blades are commonly used and how they perform in terms of smooth cutting action.

Roofing

In the roofing industry, Hook Blades for Roofing are used to cut through roofing membranes, asphalt shingles, and other roofing materials. These materials can be tough and flexible, making them challenging to cut. Heavy duty hook blades are designed to handle these materials with ease. Their hook shape allows them to grip the material firmly, while their sharp edges can make clean, smooth cuts. This is crucial for ensuring a proper fit and seal of the roofing materials, which is essential for the long - term durability of the roof.

Manufacturing

In manufacturing, heavy duty hook blades are used for cutting a variety of materials, including plastics, rubber, and textiles. The smooth cutting action of these blades is important for maintaining the quality of the finished product. For example, when cutting rubber gaskets, a smooth cut ensures that the gasket fits properly and provides a tight seal. Using a blade with a smooth cutting action can also reduce production time and waste, as there is less need for re - cutting or finishing.

Construction

In construction, heavy duty hook blades are used for tasks such as cutting insulation materials, drywall, and sheathing. These materials require a blade that can make clean, precise cuts. The smooth cutting action of hook blades allows for efficient and accurate cutting, which is essential for the overall quality of the construction project.

Our Heavy Duty Hook Blades

As a supplier of Heavy Duty Hook Blades, we take pride in offering high - quality products that provide a smooth cutting action. Our blades are made from the finest steel alloys and are precision - ground to ensure maximum sharpness and durability. We offer a wide range of hook blades to suit different applications and materials, including Hook Razor Blade for more delicate cutting tasks.

We understand the importance of a smooth cutting action for our customers. That's why we conduct rigorous quality control tests on all our blades to ensure they meet the highest standards. Our blades are designed to provide consistent performance, whether you're a professional contractor or a DIY enthusiast.

Contact Us for Procurement

If you're in the market for heavy duty hook blades that offer a smooth cutting action, we'd love to hear from you. Our team of experts can help you choose the right blade for your specific needs. Whether you have questions about our products, need advice on blade selection, or are ready to place an order, we're here to assist you. Contact us today to start the procurement process and experience the difference of our high - quality heavy duty hook blades.

References

- "Cutting Tool Technology: Principles and Applications" by John A. Schey

- "Materials Science and Engineering: An Introduction" by William D. Callister, Jr. and David G. Rethwisch