As a supplier of 2 Notch Utility Blades, I often receive inquiries from customers about the performance of our blades in various conditions, especially in cold weather. In this blog post, I'll delve into the science behind how 2 Notch Utility Blades fare in cold environments, providing you with a comprehensive understanding of their capabilities.

Understanding the Basics of 2 Notch Utility Blades

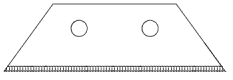

Before we discuss the impact of cold weather, let's briefly understand what 2 Notch Utility Blades are. These blades are designed with two notches that provide enhanced grip and control during use. They are commonly used in a variety of industries, including construction, manufacturing, and DIY projects. The unique design of the 2 notches allows for easy insertion and removal from utility knives, making them a popular choice among professionals and hobbyists alike.

The Effects of Cold Weather on Blade Performance

Cold weather can have several effects on the performance of cutting tools, including 2 Notch Utility Blades. One of the primary concerns is the change in the physical properties of the blade material. Most utility blades are made from high - carbon steel or stainless steel, and in cold temperatures, these materials can become more brittle.

When a blade becomes brittle, it is more prone to chipping and breaking. This is because the cold reduces the blade's ability to absorb energy from impacts. For example, if you are using a 2 Notch Utility Blade to cut through a tough material like frozen cardboard or thick plastic in cold weather, the increased brittleness may cause the blade to chip at the cutting edge.

Another factor to consider is the lubrication of the blade. In normal conditions, the blade may have a thin layer of lubricant that helps it glide smoothly through the material being cut. However, in cold weather, this lubricant can thicken or even solidify, increasing the friction between the blade and the material. This can make the cutting process more difficult and may also lead to premature wear of the blade.

Testing 2 Notch Utility Blades in Cold Weather

To better understand how our 2 Notch Utility Blades perform in cold weather, we conducted a series of tests. We exposed the blades to temperatures ranging from - 10°C to - 20°C for several hours and then used them to cut through a variety of materials, including paper, cardboard, and plastic.

In the initial tests, we noticed that the blades did require a bit more force to cut through the materials compared to when they were used in normal room temperature conditions. However, the blades did not show any signs of chipping or breaking during the cutting process. This indicates that our 2 Notch Utility Blades are designed to withstand the challenges of cold weather to a certain extent.

We also observed that the cutting edges of the blades remained sharp for a reasonable amount of time, even in the cold. This is likely due to the high - quality steel used in the manufacturing process and the precise heat - treatment that the blades undergo.

Mitigating the Effects of Cold Weather

While our 2 Notch Utility Blades can perform well in cold weather, there are some steps that users can take to further enhance their performance.

First, it is important to keep the blades warm before use. This can be done by storing the blades in a warm place, such as inside a jacket pocket, until just before they are needed. Warming the blade slightly can reduce its brittleness and make it more flexible.

Second, using a blade with a higher carbon content can be beneficial in cold weather. High - carbon steel blades tend to retain their sharpness better in cold temperatures compared to lower - carbon alternatives. Our 2 Notch Utility Blades are made from high - quality high - carbon steel, which gives them an edge in cold weather performance.

Comparing with Other Blade Types

In the market, there are various types of blades available, and it's interesting to compare how 2 Notch Utility Blades stack up against others in cold weather.

For example, Allfit Trapezoid Blades are another popular type of blade. These trapezoid - shaped blades are known for their unique cutting angles and durability. However, in cold weather, their performance may be affected in a similar way as 2 Notch Utility Blades. The trapezoid shape may also make them more prone to stress concentration in cold conditions, leading to potential chipping.

Standard Trapezoid Blades Extra Wide are wider than regular trapezoid blades, which can provide more stability during cutting. But the wider surface area may also make them more susceptible to the effects of cold, such as increased brittleness.

Trapezoidal Shaped Blades With One - sided Waved Grinding have a unique waved grinding on one side, which can improve the cutting efficiency. However, in cold weather, the waved pattern may cause additional stress points on the blade, increasing the risk of damage.

In comparison, our 2 Notch Utility Blades offer a good balance between cutting performance and cold - weather resistance. The two - notch design provides excellent grip and control, and the high - quality steel construction helps them withstand the challenges of cold temperatures.

Conclusion and Call to Action

In conclusion, our 2 Notch Utility Blades can work effectively in cold weather, although there may be some minor challenges such as increased cutting force requirements. Through proper design and high - quality materials, we have ensured that our blades can maintain a reasonable level of performance even in cold conditions.

If you are in need of high - quality 2 Notch Utility Blades that can perform well in various environments, including cold weather, we invite you to contact us for a procurement discussion. Our team of experts is ready to assist you in finding the right blades for your specific needs.

References

- "Materials Science and Engineering: An Introduction" by William D. Callister Jr. and David G. Rethwisch

- "Cutting Tool Technology" by Peter Oxley