Can Trapezoidal Shaped Blades Be Used in Glass Cutting?

In the realm of industrial and precision cutting, the choice of blade is crucial, especially when it comes to cutting delicate materials like glass. One type of blade that has caught the attention of many in recent years is the trapezoidal shaped blade. As a supplier of Trapezoidal Shaped Blades, I am often asked whether these blades can be effectively used in glass cutting. In this blog post, we will explore this question in detail, considering the properties of trapezoidal shaped blades and the requirements of glass cutting.

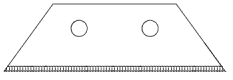

Understanding Trapezoidal Shaped Blades

Trapezoidal shaped blades are distinct from traditional rectangular or circular blades. Their unique shape, with two parallel sides of different lengths and two non - parallel sides, offers several advantages. These blades are available in various forms, such as Trapezoid Razor Blades Safety Blade and Trapezoid Blades for Utility Knives.

The trapezoidal design allows for a more focused cutting edge. The varying lengths of the parallel sides can be engineered to provide different levels of cutting force and precision. For example, a blade with a shorter top parallel side and a longer bottom parallel side can concentrate the cutting pressure at the tip, enabling more accurate incisions. Additionally, the non - parallel sides can enhance the blade's stability during cutting, reducing the risk of slippage.

The Requirements of Glass Cutting

Glass is a brittle and hard material, which means that cutting it requires a high level of precision and control. A successful glass cut should result in a clean, straight edge without chipping or cracking. To achieve this, the cutting blade needs to have the following characteristics:

- Sharpness: A sharp blade is essential to make a clean cut through the glass without causing excessive stress that could lead to breakage. The blade should be able to penetrate the glass surface smoothly and create a precise score line.

- Hardness: Since glass is a hard material, the blade must be harder than the glass to ensure that it can cut through effectively. A blade with insufficient hardness will dull quickly, resulting in uneven cuts and a shorter lifespan.

- Stability: During the cutting process, the blade needs to remain stable to maintain a straight and consistent cut. Any wobbling or movement of the blade can cause the glass to crack or chip.

Analyzing the Suitability of Trapezoidal Shaped Blades for Glass Cutting

- Sharpness: Trapezoidal shaped blades can be manufactured with extremely sharp edges. Advanced grinding and sharpening techniques can be applied to the trapezoidal shape to create a fine cutting edge. The unique geometry of the trapezoid can also contribute to the concentration of cutting forces at the tip, enhancing the blade's ability to make a sharp incision in the glass. For instance, the one - sided waved grinding of Trapezoidal Shaped Blades With One - sided Waved Grinding can further improve the sharpness and cutting performance.

- Hardness: Our trapezoidal shaped blades are made from high - quality materials with excellent hardness properties. We use premium alloys and heat - treatment processes to ensure that the blades can withstand the high pressures and abrasion associated with glass cutting. This means that the blades can maintain their sharpness and cutting ability for a longer period, reducing the frequency of blade replacement.

- Stability: The trapezoidal shape provides inherent stability to the blade. The non - parallel sides act as guides, helping to keep the blade in place during the cutting process. This stability is crucial for making straight and accurate cuts in glass. Additionally, the design of the blade can be optimized to fit specific cutting tools, further enhancing its stability.

Case Studies and Practical Applications

In practical applications, trapezoidal shaped blades have shown promising results in glass cutting. For example, in the manufacturing of glass windows and mirrors, these blades have been used to make precise cuts with minimal chipping. In the electronics industry, where glass components are used in displays and touchscreens, trapezoidal shaped blades have been employed to cut thin glass sheets with high precision.

One customer reported that after switching to our trapezoidal shaped blades for their glass cutting operations, they noticed a significant improvement in the quality of their cuts. The blades were able to make cleaner and more accurate cuts, reducing the number of defective products. Another customer in the art glass industry found that the unique shape of the trapezoidal blades allowed them to create more intricate and detailed cuts, expanding their creative possibilities.

Challenges and Considerations

While trapezoidal shaped blades offer many advantages for glass cutting, there are also some challenges and considerations to keep in mind. One challenge is the initial cost of the blades. Due to the complex manufacturing processes and high - quality materials used, trapezoidal shaped blades may be more expensive than traditional blades. However, when considering the longer lifespan and improved cutting quality, the overall cost - effectiveness can be quite high.

Another consideration is the compatibility of the blade with the cutting equipment. It is important to ensure that the trapezoidal shaped blade is properly installed and adjusted in the cutting tool to achieve the best results. Additionally, the operator's skill and experience also play a role in the success of the glass cutting process.

Conclusion

In conclusion, trapezoidal shaped blades can indeed be used in glass cutting. Their unique shape, sharpness, hardness, and stability make them well - suited for the precision and control required in glass cutting applications. While there are some challenges and considerations, the benefits of using trapezoidal shaped blades outweigh the drawbacks.

If you are in the glass cutting industry and are looking for a high - performance blade solution, we invite you to explore our range of Trapezoidal Shaped Blades. Our team of experts is available to provide you with more information and support. Contact us to discuss your specific requirements and start a procurement negotiation. We are confident that our trapezoidal shaped blades will meet your expectations and enhance the efficiency and quality of your glass cutting operations.

References

- "Advanced Cutting Technologies in the Glass Industry" - Journal of Industrial Cutting

- "Materials Science for Precision Blades" - Materials Research Journal

- Customer case studies and feedback from glass cutting companies