In the dynamic environment of a workshop, the choice of tools can significantly impact the efficiency and safety of operations. One such tool that has gained attention is the Hook Blade Box Cutter. As a supplier of these specialized cutters, I am often asked, "Can I use a Hook Blade Box Cutter in a workshop?" This blog post aims to explore the viability, advantages, and considerations of using a Hook Blade Box Cutter in a workshop setting.

Understanding the Hook Blade Box Cutter

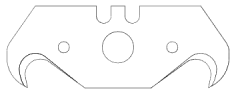

Before delving into its suitability for a workshop, it's essential to understand what a Hook Blade Box Cutter is. A Hook Blade Box Cutter is a cutting tool characterized by its unique hook-shaped blade. This design provides several benefits, including enhanced control and precision when cutting through various materials. The hook blade allows for a more secure grip on the material being cut, reducing the risk of slippage and ensuring a cleaner cut.

There are different types of hook blades available, each designed for specific applications. For instance, Hook Blades for Roofing are engineered to handle the tough materials commonly found in roofing projects, such as asphalt shingles and felt paper. On the other hand, Heavy Duty Hook Blades are built to withstand more rigorous cutting tasks, making them suitable for industrial workshops.

Advantages of Using a Hook Blade Box Cutter in a Workshop

- Precision Cutting

One of the primary advantages of using a Hook Blade Box Cutter in a workshop is its ability to provide precise cuts. The hook-shaped blade allows for better control over the cutting process, enabling workers to make accurate cuts even in tight spaces or along curved lines. This precision is particularly valuable when working on projects that require high levels of accuracy, such as woodworking or metal fabrication. - Versatility

Hook Blade Box Cutters are highly versatile tools that can be used to cut a wide range of materials. From cardboard and plastic to leather and fabric, these cutters can handle various materials with ease. This versatility makes them a valuable addition to any workshop, as they can be used for multiple tasks without the need for multiple tools. - Safety

Safety is a top priority in any workshop, and Hook Blade Box Cutters are designed with safety in mind. The hook-shaped blade reduces the risk of accidental cuts by providing a more secure grip on the material being cut. Additionally, many Hook Blade Box Cutters feature safety mechanisms, such as retractable blades or blade guards, to further minimize the risk of injury. - Efficiency

Using a Hook Blade Box Cutter can significantly improve the efficiency of workshop operations. The precise cuts provided by these cutters reduce the need for additional finishing work, saving time and labor costs. Additionally, the versatility of Hook Blade Box Cutters means that workers can switch between different tasks more quickly, increasing overall productivity.

Considerations When Using a Hook Blade Box Cutter in a Workshop

While Hook Blade Box Cutters offer many advantages, there are also some considerations to keep in mind when using them in a workshop.

- Material Compatibility

Before using a Hook Blade Box Cutter on a particular material, it's important to ensure that the blade is compatible with the material. Different materials require different types of blades, and using the wrong blade can result in a poor cut or damage to the tool. For example, using a blade designed for soft materials on a hard material can cause the blade to dull quickly or break. - Blade Maintenance

Proper blade maintenance is essential to ensure the longevity and performance of a Hook Blade Box Cutter. Regularly sharpening or replacing the blade will help maintain its cutting edge and prevent it from becoming dull or damaged. Additionally, keeping the blade clean and free of debris will help prevent rust and corrosion, which can affect the performance of the tool. - Training and Safety Procedures

Workers should receive proper training on how to use a Hook Blade Box Cutter safely and effectively. This includes understanding the tool's features and functions, as well as following proper safety procedures, such as wearing protective gear and using the tool in a well-ventilated area. Providing workers with the necessary training and resources will help ensure that they can use the tool safely and efficiently.

Applications of Hook Blade Box Cutters in a Workshop

Hook Blade Box Cutters can be used in a variety of applications in a workshop. Some common applications include:

- Packaging and Shipping

In a workshop that deals with packaging and shipping, Hook Blade Box Cutters are essential tools for opening boxes and cutting packing materials. The precise cuts provided by these cutters ensure that boxes can be opened without damaging the contents, while the versatility of the tool allows for cutting through different types of packaging materials, such as cardboard, plastic, and tape. - Woodworking

In woodworking, Hook Blade Box Cutters can be used for a variety of tasks, such as cutting veneer, trimming edges, and making precise cuts in small pieces of wood. The hook-shaped blade provides better control over the cutting process, allowing for more accurate cuts and reducing the risk of splintering or chipping. - Metal Fabrication

In metal fabrication, Hook Blade Box Cutters can be used for cutting thin sheets of metal, such as aluminum or copper. The precise cuts provided by these cutters ensure that the metal can be cut to the desired shape and size without causing any damage to the material. Additionally, the versatility of the tool allows for cutting through different types of metal, such as stainless steel and brass. - Textile and Leather Work

In textile and leather work, Hook Blade Box Cutters can be used for cutting fabrics, leather, and other materials. The precise cuts provided by these cutters ensure that the materials can be cut to the desired shape and size without fraying or tearing. Additionally, the hook-shaped blade provides better control over the cutting process, allowing for more accurate cuts and reducing the risk of making mistakes.

Conclusion

In conclusion, a Hook Blade Box Cutter can be a valuable tool in a workshop. Its precision cutting, versatility, safety features, and efficiency make it suitable for a wide range of applications. However, it's important to consider the material compatibility, blade maintenance, and training and safety procedures when using this tool. By following these guidelines, workers can use a Hook Blade Box Cutter safely and effectively, improving the efficiency and productivity of workshop operations.

If you're interested in learning more about our Hook Blade Box Cutters or discussing potential procurement opportunities, please feel free to reach out. We're always happy to assist you in finding the right tools for your workshop needs.

References

- "Tool Safety in the Workshop." Occupational Safety and Health Administration.

- "Blade Maintenance Guide." Tool Manufacturer's Handbook.

- "Applications of Hook Blade Box Cutters." Workshop Technology Journal.