In the realm of cutting tools, the versatility of blades is a crucial factor that determines their applicability across various industries and tasks. As a supplier of Allfit Trapezoid Blades, I often encounter inquiries regarding the suitability of these blades for specific cutting jobs, one of the most common being, "Can Allfit Trapezoid Blades be used for cutting paper?" In this blog post, I will delve into the characteristics of Allfit Trapezoid Blades, the nature of paper cutting requirements, and evaluate whether these blades are a viable option for this particular task.

Understanding Allfit Trapezoid Blades

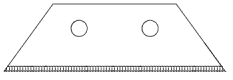

Allfit Trapezoid Blades are a unique type of cutting tool known for their distinct trapezoidal shape. This shape offers several advantages in terms of cutting performance and functionality. The trapezoidal design allows for a more stable cutting edge, which can enhance precision and control during the cutting process. Additionally, the blades are available in different variations, each tailored to specific applications.

One of the popular variants is the Trapezoidal Shaped Blades With One-sided Waved Grinding. These blades feature a waved grinding on one side, which can provide enhanced cutting efficiency, especially when dealing with materials that require a more aggressive cutting action. The waved edge helps to break through the material more easily, reducing the amount of force required for cutting.

Another type is the 2 Notch Utility Trapezoide Blades. The notches on these blades serve multiple purposes. They can act as a guide for the cutting process, ensuring a more straight and accurate cut. Moreover, the notches can also help to prevent the blade from slipping during use, providing additional safety and control.

The Trapezoid Razor Blades Safety Blade is designed with safety in mind. It typically has a protective covering or a design that minimizes the risk of accidental cuts. These blades are often used in applications where precision and safety are of utmost importance.

Paper Cutting Requirements

Paper cutting is a common task in various industries, including printing, packaging, and crafts. The requirements for paper cutting can vary depending on the type of paper, the thickness of the paper stack, and the desired cutting precision.

For thin papers, such as copy paper or tissue paper, a sharp and precise blade is required to make clean cuts without tearing or fraying the paper. The blade should be able to cut through the paper smoothly, leaving a clean edge. In some cases, where high-speed cutting is involved, the blade should also be able to maintain its sharpness over a long period of time to ensure consistent cutting quality.

When it comes to thicker papers, such as cardstock or cardboard, a more robust blade is needed. The blade should have enough strength to cut through the thicker material without bending or breaking. Additionally, the cutting edge should be able to withstand the higher pressure required for cutting thicker papers.

Precision is also a key factor in paper cutting. Whether it's cutting a single sheet of paper or a stack of papers, the blade should be able to make accurate cuts according to the desired dimensions. This is particularly important in industries such as printing and packaging, where precise cuts are essential for the final product.

Evaluating the Suitability of Allfit Trapezoid Blades for Paper Cutting

Sharpness

One of the most important factors in paper cutting is the sharpness of the blade. Allfit Trapezoid Blades are generally made from high-quality materials and are manufactured with precision grinding processes to ensure a sharp cutting edge. The sharpness of these blades can be sufficient for cutting thin papers, such as copy paper and tissue paper. The smooth cutting action of the blades can result in clean cuts without tearing or fraying the paper.

However, for thicker papers, the sharpness of the blade may need to be evaluated more carefully. While the blades are sharp, the thickness and density of the paper can put more stress on the cutting edge. In some cases, the blade may need to be replaced more frequently to maintain the desired cutting quality.

Cutting Precision

The trapezoidal shape of Allfit Trapezoid Blades provides a stable cutting edge, which can contribute to better cutting precision. The shape helps to keep the blade in place during the cutting process, reducing the chances of the blade wandering or deviating from the desired cutting line. This is particularly beneficial when cutting multiple sheets of paper at once or when making precise cuts in paper crafts.

The notches on the 2 Notch Utility Trapezoide Blades can also enhance cutting precision. They can act as a guide, ensuring that the blade follows a straight path and makes accurate cuts. This feature can be very useful in applications where precise cuts are required, such as in the production of greeting cards or paper models.

Durability

Durability is another important consideration when using blades for paper cutting. Allfit Trapezoid Blades are designed to be durable and long-lasting. The high-quality materials used in their manufacturing can withstand the wear and tear of regular use. However, the durability of the blades can be affected by the type of paper being cut.

When cutting thin papers, the blades can generally maintain their sharpness and integrity for a relatively long time. But when dealing with thicker papers or papers with a rough surface, the blades may experience more wear. In such cases, it is important to monitor the condition of the blades and replace them when necessary to ensure consistent cutting performance.

Safety

Safety is always a concern when using cutting tools. The Trapezoid Razor Blades Safety Blade is designed with safety features to minimize the risk of accidental cuts. This can be especially important in paper cutting tasks, where the operator may be handling the blades frequently.

The design of the blade, such as the protective covering or the shape that reduces the exposure of the cutting edge, can provide an additional layer of safety. This is particularly beneficial in environments where there are multiple operators or where the cutting task is being performed by individuals with limited experience.

Conclusion

In conclusion, Allfit Trapezoid Blades can be suitable for paper cutting, depending on the specific requirements of the task. For thin papers, these blades can provide sharp and precise cuts, making them a viable option for tasks such as copying, printing, and crafts. The sharpness and cutting precision of the blades can ensure clean and accurate cuts without damaging the paper.

When it comes to thicker papers, the blades may still be used, but the durability and cutting performance may need to be carefully monitored. The strength and robustness of the blades can allow them to cut through thicker materials, but the wear on the cutting edge may be more significant.

If you are in the market for high-quality blades for paper cutting or other applications, I encourage you to consider Allfit Trapezoid Blades. Our blades are designed to meet the diverse needs of various industries, and we are committed to providing the best products and services to our customers. If you have any questions or would like to discuss your specific requirements, please feel free to contact us for a procurement negotiation.

References

- General knowledge about cutting tools and paper cutting requirements.

- Product specifications and features of Allfit Trapezoid Blades.