Are trapezoidal shaped blades compatible with different cutting machines?

As a supplier of trapezoidal shaped blades, I've been frequently asked about the compatibility of these unique blades with various cutting machines. In this blog, I'll delve into the factors that determine this compatibility and provide insights based on my years of experience in the industry.

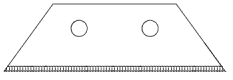

Understanding Trapezoidal Shaped Blades

Trapezoidal shaped blades come in a variety of forms, each designed to meet specific cutting requirements. For instance, our Standard Trapezoid Blades Extra Wide offer a wider cutting surface, which is ideal for applications that demand more coverage. These blades are precision - engineered to ensure clean and efficient cuts.

Another popular type is the Trapezoidal Shaped Blades With One - sided Waved Grinding. The one - sided waved grinding provides enhanced cutting performance, especially when dealing with materials that require a more aggressive cutting action.

Our 2 Notch Utility Trapezoide Blades are designed with two notches, which can be used for specific cutting techniques or to fit into certain machine setups.

Factors Affecting Compatibility

Machine Type

There are numerous types of cutting machines in the market, such as guillotine cutters, rotary cutters, and band saws. Each machine has its own unique design and operating mechanism.

Guillotine cutters work by a vertical blade that descends to make a straight cut. Trapezoidal blades can be used in guillotine cutters if the blade dimensions and mounting requirements are met. The shape of the trapezoid can be advantageous as it can provide a more stable cutting edge compared to a rectangular blade in some cases.

Rotary cutters, on the other hand, use a rotating blade to cut through materials. Compatibility here depends on the blade's diameter, thickness, and the speed at which it can rotate. Our trapezoidal blades can be adapted to rotary cutters with proper engineering and customization. The unique shape of the trapezoid can also help in achieving a more consistent cut as the blade rotates.

Band saws have a continuous band of blade that runs around two or more wheels. Trapezoidal blades can be used in band saws, but the blade needs to be flexible enough to conform to the curvature of the wheels while maintaining its cutting performance.

Material to be Cut

The material being cut also plays a crucial role in determining the compatibility of trapezoidal blades with cutting machines. Different materials have different hardness, toughness, and abrasiveness.

For soft materials like paper, cardboard, and fabric, trapezoidal blades can be used in a wide range of cutting machines. The shape of the blade allows for efficient cutting without causing excessive tearing or fraying. Our standard trapezoid blades are well - suited for these types of materials.

When it comes to harder materials such as plastics, metals, and composites, the blade needs to be made of a high - quality material with appropriate heat treatment. Our trapezoidal blades with one - sided waved grinding are often a good choice for these materials as they can provide a more aggressive cutting action. However, the cutting machine needs to be powerful enough to handle the resistance offered by these hard materials.

Mounting and Adaptability

The way the blade is mounted on the cutting machine is a critical factor in compatibility. Different machines have different mounting systems, such as clamp - on, bolt - on, or magnetic mounting.

Our trapezoidal blades can be designed with different mounting options to fit various machines. For example, we can add holes or slots to the blade for bolt - on mounting. In some cases, we can also provide custom - made adapters to ensure that the blade can be securely mounted on the machine.

Benefits of Using Trapezoidal Shaped Blades in Different Machines

Enhanced Cutting Performance

The trapezoidal shape of the blade can provide a more stable cutting edge compared to traditional rectangular blades. This stability results in cleaner and more precise cuts, especially when cutting through thick or tough materials. In a guillotine cutter, for example, the trapezoidal blade can apply more pressure evenly across the cutting surface, reducing the chances of the material shifting during the cut.

Versatility

Trapezoidal shaped blades can be used in a wide range of applications. Whether it's cutting straight lines, curves, or making intricate cuts, these blades can be adapted to different cutting requirements. In a rotary cutter, the trapezoidal blade can be used to cut both large - scale patterns and small, detailed designs.

Longer Blade Life

Due to their unique shape, trapezoidal blades can distribute the cutting forces more evenly. This reduces the wear and tear on the blade, resulting in a longer blade life. In a band saw, for instance, the trapezoidal blade can withstand the continuous stress of cutting without losing its cutting performance quickly.

Case Studies

Let's take a look at a few real - world examples of how our trapezoidal shaped blades have been successfully used with different cutting machines.

A paper manufacturing company was using a guillotine cutter to cut large rolls of paper into smaller sheets. They were facing issues with uneven cuts and frequent blade changes. After switching to our Standard Trapezoid Blades Extra Wide, they noticed a significant improvement in the quality of the cuts. The wider blade provided more stability, and the blade life increased by almost 30%.

A plastics fabrication shop was using a rotary cutter to cut plastic sheets. They needed a blade that could provide a clean cut without melting the plastic. Our Trapezoidal Shaped Blades With One - sided Waved Grinding were the perfect solution. The waved grinding provided an aggressive cutting action, and the blade was able to cut through the plastic without overheating.

Conclusion

In conclusion, trapezoidal shaped blades can be compatible with different cutting machines, but it depends on several factors such as machine type, material to be cut, and mounting requirements. Our company offers a wide range of trapezoidal shaped blades, each designed to meet specific cutting needs. Whether you're using a guillotine cutter, a rotary cutter, or a band saw, we can provide a blade that is compatible with your machine and can deliver excellent cutting performance.

If you're interested in learning more about our trapezoidal shaped blades or would like to discuss your specific cutting requirements, we invite you to reach out to us for a procurement discussion. We're committed to providing high - quality blades and excellent customer service.

References

- "Cutting Tools and Their Applications" - A comprehensive guide on different types of cutting tools and their compatibility with various machines.

- Industry reports on the latest trends in blade technology and cutting machine design.

- In - house research and development data on the performance of trapezoidal shaped blades in different cutting scenarios.