Are hook blades for roofing easy to remove if needed?

As a long - time supplier of Hook Blades for Roofing, I've encountered numerous queries from contractors, DIY enthusiasts, and roofing professionals about the removability of these essential tools. This topic is crucial as it directly impacts the efficiency, safety, and cost - effectiveness of roofing projects. In this blog, I'll delve into the factors that determine how easy it is to remove hook blades for roofing when the need arises.

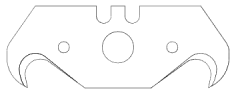

Understanding Hook Blades for Roofing

Hook blades for roofing come in various shapes, sizes, and designs, each tailored to specific roofing materials and applications. Hook Blades for Shingles are commonly used to lift and remove old shingles during roof repairs or replacements. They have a sharp, curved hook at one end that can easily slide under the shingles and pry them loose. On the other hand, Heavy Duty Hook Blades are built to handle more robust roofing materials such as metal or slate. These blades are thicker, stronger, and often have reinforced edges to withstand the extra stress.

Factors Affecting the Ease of Removal

- Installation Method

The way hook blades are installed plays a significant role in their removability. If they are simply placed in a holder or bracket without any additional fastening, they can be easily removed. However, some hook blades are installed using nails, screws, or adhesives for a more secure fit. In such cases, removal can be more challenging. For example, if nails are used to attach the blade to a handle, removing the blade requires a nail - pulling tool. This process can be time - consuming and may damage the blade or the handle if not done carefully. - Roofing Material

The type of roofing material the hook blade is used on also affects its removal. When working with soft materials like asphalt shingles, the hook blade can be inserted and removed relatively easily. The shingles are flexible, and the blade can be maneuvered without much resistance. In contrast, when dealing with hard materials like slate or concrete tiles, the blade may get stuck or jammed. These materials are brittle and can break, causing pieces to lodge around the blade and making removal difficult. - Blade Design

The design of the hook blade itself is another crucial factor. Some blades have a simple, straight - forward design that allows for easy insertion and removal. Others may have complex shapes or features that make removal more challenging. For instance, a blade with a deep hook or a serrated edge may grip the roofing material more tightly, making it harder to pull out. Additionally, blades with a large surface area in contact with the roofing material may create more friction, increasing the difficulty of removal. - Condition of the Blade and Roof

Over time, hook blades can become worn, bent, or corroded. A damaged blade may not fit properly in the holder or may get stuck in the roofing material. Similarly, if the roof has been damaged or has debris accumulated around the area where the blade is inserted, removal can be more difficult. For example, if there is a build - up of dirt or moss on the shingles, it can act as a barrier, preventing the blade from being easily removed.

Techniques for Easy Removal

- Proper Use of Tools

Using the right tools is essential for easy removal of hook blades. For blades attached with nails, a nail - pulling tool such as a claw hammer or a cat's paw can be used. If screws are used, a screwdriver of the appropriate size and type should be employed. For adhesively - attached blades, a heat gun can be used to soften the adhesive, making it easier to separate the blade from the handle or the roofing material. - Lubrication

Applying a lubricant such as silicone spray or WD - 40 to the blade before installation can reduce friction and make removal easier. The lubricant creates a slippery surface between the blade and the roofing material or the holder, allowing the blade to slide out more smoothly. However, it's important to use the right amount of lubricant, as too much can make the blade difficult to grip during use. - Pre - Planning

Before starting a roofing project, it's a good idea to plan for the removal of hook blades. This includes choosing the right type of blade for the job, considering the installation method, and having the necessary tools on hand. For example, if you know that you'll need to remove the blade frequently, opt for a blade that can be easily installed and removed without the need for complex fastening methods.

Benefits of Easy Removal

- Efficiency

Easy removal of hook blades saves time during roofing projects. If a blade gets stuck or is difficult to remove, it can slow down the entire process. Contractors can quickly switch out blades when needed, allowing them to work more efficiently and complete the project faster. - Cost - Effectiveness

When hook blades are easy to remove, they can be reused or replaced more easily. This reduces the need to purchase new blades frequently, saving money in the long run. Additionally, if a blade can be removed without causing damage to the handle or other components, it can extend the lifespan of the tool. - Safety

Difficult removal of hook blades can pose safety risks. Workers may use excessive force to remove a stuck blade, which can lead to injuries such as cuts or strains. Easy removal reduces the risk of such accidents, ensuring a safer working environment.

Conclusion

In conclusion, whether hook blades for roofing are easy to remove depends on several factors, including the installation method, roofing material, blade design, and the condition of the blade and roof. While some situations may present challenges, following proper techniques and using the right tools can make the removal process relatively easy. As a supplier of Hook Blades for Roofing, I understand the importance of providing products that are not only effective but also easy to use and maintain.

If you're involved in a roofing project and are looking for high - quality hook blades that are easy to remove, we'd love to hear from you. Our team of experts can provide you with the right advice and products to meet your specific needs. Contact us to start a discussion about your roofing requirements and explore our range of hook blades.

References

- "Roofing Materials and Their Impact on Tool Use" - Journal of Construction Technology

- "Best Practices for Installing and Removing Roofing Tools" - Construction Industry Magazine

- "Hook Blade Design and Functionality" - Tool Manufacturing Research Journal