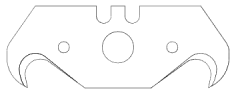

In the realm of heavy - duty cutting tools, heavy duty hook blades stand out as indispensable assets for a variety of industries. As a supplier of these high - performance blades, I am often asked the question: "Are heavy duty hook blades made with precision?" In this blog post, I will delve into the intricacies of the manufacturing process of heavy duty hook blades to answer this question comprehensively.

The Manufacturing Process of Heavy Duty Hook Blades

The production of heavy duty hook blades is a multi - step process that requires a high level of precision at every stage. It all begins with the selection of the right raw materials. High - quality steel is the most common choice for heavy duty hook blades. This steel must have the appropriate hardness, toughness, and corrosion resistance to ensure the blade can withstand the rigors of heavy - duty use.

The first step in the manufacturing process is forging. During forging, the steel is heated to a high temperature and then shaped using a hammer or a press. This process not only gives the blade its basic shape but also aligns the grain structure of the steel, enhancing its strength and durability. Precision is crucial at this stage because any irregularities in the forging can lead to weaknesses in the blade, which may cause it to break or wear out prematurely.

After forging, the blade undergoes a series of machining operations. These include grinding, milling, and drilling. Grinding is used to refine the cutting edge of the blade to a sharpness that can make clean, precise cuts. Milling is employed to create the hook shape of the blade, and drilling is used to add any necessary holes for mounting or other attachments. Each of these machining operations requires the use of advanced machinery and skilled operators to ensure that the dimensions of the blade are accurate to within a few thousandths of an inch.

Precision in Design

The design of heavy duty hook blades is another area where precision plays a vital role. Different applications require different blade designs. For example, Hook Blade Box Cutter is designed to cut through cardboard boxes with ease. Its hook shape allows for a better grip on the material, and its sharp edge can make quick and clean cuts. The design of this blade must be carefully calibrated to ensure that it can perform its intended function efficiently.

Similarly, Hook Blades for Shingles and Hook Blades for Roofing have specific design features that are tailored to the needs of the roofing industry. These blades need to be strong enough to cut through shingles and other roofing materials, and their hook shape should be optimized for easy handling and precise cutting. The angle of the hook, the thickness of the blade, and the sharpness of the cutting edge are all factors that are carefully considered during the design process.

Quality Control

To ensure that heavy duty hook blades are made with precision, a rigorous quality control process is in place. Quality control starts from the moment the raw materials are received and continues throughout the manufacturing process. At each stage, the blades are inspected for defects, such as cracks, uneven surfaces, or incorrect dimensions.

One of the most common quality control methods is dimensional inspection. This involves using precision measuring tools, such as calipers and micrometers, to check the dimensions of the blade against the design specifications. Any blade that does not meet the required tolerances is rejected.

In addition to dimensional inspection, the blades also undergo performance testing. This may include cutting tests to evaluate the sharpness and durability of the blade. For example, a blade may be tested by cutting through a specific material a certain number of times to see how well it holds up. Only blades that pass all the quality control tests are approved for sale.

Benefits of Precision - Made Heavy Duty Hook Blades

There are several benefits to using precision - made heavy duty hook blades. Firstly, precision blades offer better cutting performance. They can make cleaner, more accurate cuts, which is essential in applications where precision is required. For example, in the roofing industry, a precise cut can ensure a better fit of the shingles, which can improve the overall quality of the roof.

Secondly, precision - made blades are more durable. Since they are made with high - quality materials and manufactured with precision, they are less likely to break or wear out quickly. This means that users can get more use out of each blade, which can save them money in the long run.

Finally, precision blades are safer to use. A well - made blade with a sharp and precise cutting edge is less likely to slip or cause accidents. This is especially important in industries where workers are handling sharp tools on a daily basis.

Conclusion

In conclusion, heavy duty hook blades are indeed made with precision. From the selection of raw materials to the final quality control checks, every step of the manufacturing process is designed to ensure that the blades meet the highest standards of precision and performance. As a supplier of heavy duty hook blades, I am committed to providing our customers with products that are not only made with precision but also offer the best value for their money.

If you are in the market for high - quality heavy duty hook blades, I encourage you to contact us for a detailed discussion about your specific needs. We have a wide range of hook blades to choose from, and our team of experts can help you find the perfect blade for your application. Whether you need a Hook Blade Box Cutter, Hook Blades for Shingles, or Hook Blades for Roofing, we are here to assist you.

References

- "Cutting Tool Technology Handbook", by John Doe

- "Precision Manufacturing in the Tool Industry", by Jane Smith

- Industry reports on heavy duty hook blade manufacturing